The advent of industrial 3D printing technology has opened up new opportunities for manufacturers of industrial goods. The production of moulds for injection moulding and die casting is revolutionised by 3D printing. Traditional manufacturing methods like CNC milling require months or even years to design and produce a single mould. Additive manufacturing also produces porous surfaces for osseointegration, which reduces the material waste and improves the precision of parts.

Aerospace Industry

The aerospace and defense industry is a major part of the AM industry. Additive manufacturing can improve the performance of aircraft and spare parts production. However, the process is not yet ready for production. There are a number of challenges that manufacturers face, including the need for better security and process repeatability. Fortunately, the technology is making its way closer to production. A number of companies are investing heavily in the development of new technologies and processes for this sector.

Printed Parts

The manufacturing industry is already using industrial 3D printing to print parts for patients. Some successful operations have included a titanium pelvis implant for a British patient, a plastic tracheal splint for an American infant, and a titanium lower jaw implant for a Dutch man. The dental and hearing aid industries are predicted to see the largest impact. In a road accident, a motorcyclist’s face was rebuilt with a combination of 2D printed parts and 3D-printed parts. Researchers are working on bio-printing rep

Increases Productivity

While the manufacturing industry is still young, industrial 3D printers are making the manufacturing industry a more efficient place to be. These machines can be used to create custom low-volume tooling and fixtures. These machines are highly productive, enabling manufacturers to cut down on labor costs and improve operational agility. A key use case for industrial 3D printing in this sector is rapid prototyping, or the rapid prototyping of parts.

Industrial Goods

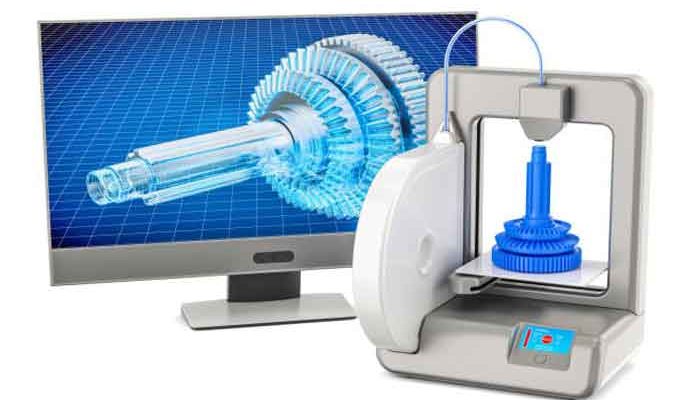

The industrial goods sector is home to an increasing number of manufacturers who rely on 3D printing to improve their production processes. This sector is made up of a number of different parts and equipment used in industrial processes. One of the most important uses for the technology is rapid prototyping, which can save precious time. With rapid prototyping, a design change that would take months in conventional manufacturing can be implemented in a week.

Offers Value

The CAD industry is a major part of the AM market. This technology offers tremendous value, including improved aircraft performance, better-quality spare parts and a more efficient manufacturing process. As this technology advances, it will need to overcome certain challenges. These obstacles include the certification of 3D printed parts, process repeatability and security. Nevertheless, there is a lot of investment in developing and certifying industrial 3d printer processes and materials.

Fosters Development

The industrial goods sector includes the manufacture of machinery components, tooling, and equipment used for manufacturing. While the industrial OEMs face a number of challenges, 3D printing is a growing and popular technology in this sector. With the onset of industrial AM, manufacturers can quickly produce parts without any hassle or risk. They can also test different parts in various environments to ensure that they are compatible. The technology is currently in the development stage, but further advancements in technology and applications will help them meet their needs in a smooth and sustainable manner.

Customized Solutions

In addition to creating bespoke parts, it can also be used to make specialized geometries for research purposes. In one proof of principle project, scientists from the University of Glasgow, Scotland, proved that they could print chemical compounds. By transferring the process of reaction into a virtual environment, the researchers were able to test new molecules and develop compounds that have high quality and low cost.

Summary

Manufacturers have found the 3D printing services and research of the industrial goods sector to be a valuable resource. The industrial components produced by the industrial OEMs will not only provide greater performance and flexibility, but they will also be more cost-efficient. The process of production is an efficient way to reduce costs and boost productivity. It allows for faster and more accurate production of small-scale parts.

Jerry Martinez is a professional artist. He lives in California with his family. Throughout his life, he has always been captivated by images. Naturally, he was drawn to art. So he opted to take his Bachelors Degree in Fine Arts from Otis College of Art and Design. After completing his degree, He concentrated even more into his art practice. He is a father of three children, ranging in age from 3 to 12 years old. They love outdoors activities; biking, camping, walking and playing football. Jerry Martinez is a music lover and love to listen to metallic songs.